|

100 MHz LOW NOISE XTAL OSCILLATOR FOR SPACE APPLICATION 1- Abstract A.R.Electronique, in collaboration with the CNES has investigated for a new kind of 100 MHz oscillator used for frequency synthesis. This original oscillator’s design is dedicated for the specific environemental requirements in space applications, like PHARAO program. Usually, we are tempted to develop an ovenized oscillator (OCXO) with the highest level of performances for phase noise and temperature behavior. But, on the other side, the ovenized solution leads to more complexity, and to mass, consumption, and resonator’s aging increasement. In this paper we describe our solution without any oven, based on the use of an optimized crystal resonator cut dedicated to a narrow operating temperature range [+10, +50]°C. The design, including our specific XTAL, will be discussed with an analysis on the global requirement for space application. A detailed comparison between OCXO and free oven XO will justify our solution. A presentation of experimental results obtained with the new structure will pointed out the enhanced parameters. A final discussion of potential other applications of this basic structure will conclude this paper. 2- Specificities of this oscillator’s requirements Thermal aspect In this space application, the thermal operating profile is very particular. The external temperature variation is < 1°C near a middle value TM, and there is a slow evolution of TM during the mission. The middle temperature evolution is about few degrees for a five years mission. According to this small temperature operating range, we don’t really need a high level of thermal regulation for this application. Mechanical aspect We need a hardened oscillator’s enclosure in order to resist at the high vibration and shock level during launch step. However, in operating mode there’re no specific requirements on g sensitivity. Volume and mass have to be minimized as much as possible. Electrical aspect 100 MHz oscillator used in synthesis chain gives a good compromize between reference and final output frequency to reach a high level of phase noise performance. This one allows a good S/N ratio either with a high multiplication level of the frequency. However, the relatively poor intrinsec long term stability leads to lock this UHF oscillator on a ultra stable frequency reference USO). In order to be compatible with the PLL locking bandwith, during the mission, we have to mimize all the frequency deviation effects, like thermal and aging behavior (we can neglect frequency pulling and pushing). The more the frequency deviation due to these effects is important, the more we have to increase the tuning sensitivity. But it has a direct degradation effect on the phase noise behavior up to 1 KHz of the carrier. A.R.Electronique has investigated on different oscillators concept in order to find the best compromize : phase noise / tuning sensitivity / complexity / reliability. The free oven XO seems to be a good alternative in small operating temperature range. 3- Oscillator description and comparaison with OCXO Fig.3.1 : Electrical synoptic Actually, the best way to reduce phase noise a small as possible is to integrate a SC cut crystal in the oscillator. On the other hand, we need an ovenized structure in order to maintain the quartz temperature at the turn over point.(TOP). When operating, the quartz temperature is few degrees upper than the upper range temperature point. It induces an aging performance degradation, but with a such ovenized oscillator, DF/F can reach ~1.10-8 for an external temperature range of about 50°C. A.R.Electronique has developed an original quartz resonator designed with a particular cut (SCD) able to preserve SC cut properties (stress behavior, phase noise…) with a turning point in the middle of the operating temperature range. In this case the quartz frequency deviation is limited to ~5ppm instead of ~100ppm for standard angle SC cut. For thermal aspect, in comparaison with AT cut we obtain a comparable frequency deviation. But for PHARAO application the reel temperature excursion is < 10°C, the temperature dependance is reduced around the TOP (~30°C) with this SCD quartz. Fig.3.2 : quartz thermal behavior Mechanical behavior The resonator is mounted on a 4 points hardened structure in

a T05 enclosure. It’s naturally able to resist to shock and vibration space

profiles (mechanical resonances are beyond 6 KHz). Fig.3.3 : excitation profile “A.R.E.” 5 grms The experimental set up and the oscillator under test is shown fig.3.4 : Fig.3.4 : experimental set up The vibration profile effect on phase noise behavior can be calculated by : We obtain the g sensitivity K : Where :

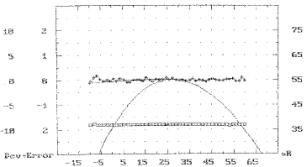

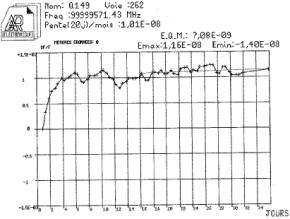

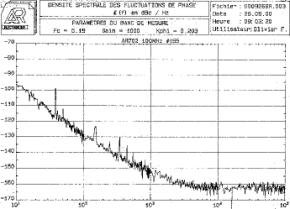

We can notice that the measured phase noise under vibration (Fig 3.5) is very close to the calculated phase noise degradation profile by formula (1) : white noise in the range [60 Hz – 100 Hz], F-2 noise in the [100 Hz – 1 kHz] decade. Spurious from 2 KHz and up to 100 kHz are induced by excitator resonance frequencies and electrical spurious from vibrating set up. The experimental result obtained fig.3.5 leads to a g sensitivity in the tested axis (perpendicular to the plate) about 5.10-11/g. For the integrality of the batches we have found a 3 axes g sensitivity < 1.10-10/g. This level of performance is very close to typical SC cut results. The enhanced ratio in comparison with AT cut is about 5 to 10. Fig.3.5 : phase noise under profile “A.R.E” 5 grms Thermal behavior The thermal behavior of our XO is led only by quartz frequency vs temperature response. Because of the relatively low consumption (~10mA), the internal dissipated power effect can be neglect. Vacuum and atmospheric test results are shown below. Fig.3.6 : temperature vs time profile in the temperature chambers Fig.3.7-A : F = f(T) at PATM Fig.3.7-B : F = f(T) under 10-4 torr There is not signifiant difference in thermal response under vacuum or atmospheric pressure (PATM). The temperature slope sign does no affect the result, the thermal hysteresis is reduced. The frequency jump induced by vacuum (10-4 torr) to atmospheric pressure (fig.3.8),does not exceed 3.10-8. Fig.3.8 : frequency jump vaccum to PATM For OCXO, thermal structure design is more difficult in order to keep PATM performances in vacuum condition. If convective exchange is important in thermal regulation at PATM, the vacuum behavior will completely change : the upper limit of the operating temperature can be reduced. To avoid this problem of heat evacuation, it involves a design based on conductive exchange and a minimization of internal dissipated power. For instance, we have tested a standard 100 MHz OCXO with an upper operating temperature under vacuum limited at +30°C instead of +70°C at PATM. Aging behavior Two main parameters are involved in the quartz aging behavior : Our specific cut enables the typical SC cut level of aging performances. At 100 MHz, the aging slope ratio is about 5 between our solution and a AT cut crystal. Moreover, the essential improvement is achieved by the relatively low operating temperature. For SC cut in OCXO, the average quartz temperature is nearly 70 to 80°C during the whole oscillator’s life and independently of environmental temperature conditions. In our case, it leads to a ~50°C drift in the quartz average operating temperature (TM ~30°C). We obtain an aging slope divided by two in comparaison with hundreds of 100 MHz SC cut OCXO results. Fig. 3.9 presents, for instance, an aging curve of a such free oven XO. Fig.3.9. : Example of aging curve of free oven XO Résult fig.3.9 shows an aging slope ~1.10-8/month only after 36 days of continuous operating time. For the other samples, the slope is about 1.10-8/month to 5.10-8/month. Phase noise in inert conditions Experimental results are shown fig. 3.10. Fig.3.10 : phase noise in inert condition This phase noise curve was obtained with a tuning sensitivity adjusted to compensate DF/F induced by thermal and aging effects. The total frequency excursion around the carrier is about +/- 7 ppm for a –10V < Uc < +10V tuning voltage range. Results obtained with this free oven structure are not fully at our best classical SC cut phase noise level. In comparaison the table below shows typical performances for A.R.Electronique product in AT, SC and SCD cut.

Free oven XO results are between VCXO (AT cut) and OCXO (SC cut) performance. However, the structure was tested with a SC cut crystal and has given same results, like in OCXO structure. That mean that we have to investigate the origin of phase degradation in our SCD quartz batches. A new SCD quartz manufacturing process is in development in order to stabilized phase noise behavior. Other characteristics Electrical characteristics

Case The oscillator is enclosed in a milled aluminium case. The total mass is < 25 grams. Fig.2.10 Aluminium case 4-Conclusion A.R.Electronique has developed an alternative to 100MHz ovenized oscillator. This structure is well adapted for space environmental requirements. Using a SCD cut crystal at ambient temperature enables an aging behavior enhancement. The frequency tuning range is comparable to sensitivity used in OCXO structure. Actually, phase noise results have to be improved by an adjustement of quartz process manufacturing. However, this structure gives a natural high reliability combined with low cost. Applications who need very low g sentivity at high frequency are other kind of use of this oscillator. For instance, in radar or other tactical application, it will be able to suppress mechanical damping structure with its natural very low g sensitivity. This work was supported by :Région de Franche Comté and Centre National d’Etudes Spatiales. Particular acknowledgment to Mr G. MARIANNEAU from “Laboratoire de Physique et Métrologie des Oscillateurs” for vacuum experimentations help References 1- E.GIRARDET and B. WOLCOFF High stability miniature OCXO’s for severe environmental conditions. Joint meeting european frequency and time forum – IEEE – IFCS (1999) 2- FILLER R.L. and VIG J.R. The acceleration sensitivity of quartz crystal oscillators Review proc. 41ST ASFC (1987), pp 398-408 3- TULADHAR K.K. High frequency quartz crystal oscillators for avionic systems.

|

||||||||||||||||||||||||||||||