|

JOINT

MEETING EUROPEAN FREQUENCY AND TIME FORUM - IEEE - IFCS - HIGH STABILITY, MINIATURE OCXO’s FOR SEVERE ENVIRONMENTAL CONDITIONS HIGH TEMPERATURE EFFECTS ON AGING AND RETRACE CHARACTERISTICS E. GIRARDET B. WOLCOFF

1- ABSTRACT A.R.Electronique has developed a new generation of high stability compact OCXO’s, especially designed for tactical, on board avionic / missile application or geophysical use. These oscillators are built with SC cut, low g sensitivity resonators, associated with a fully integrated electronic (monolithic ASIC). The extremely severe environmental requirements induces a hard mounted resonator’s structure, fully compatible with high stability. The extended temperature range (up to +115°C) involves a temperature regulation on the 2nd turn over point of the SC cut thermal curve, at about +120°C. After giving the environmental conditions and associated electrical requirements, the paper describes summarily the crystal resonator, oscillator and assembly designs. Practical experimental results are showed, including :

The aging and retrace behavior is especially pointed out : the effect of very high ovenized temperature is presentated, based on comparative long term stability measurements done on first and second turn-over point (characterizations on 18 months). Some other parallel oscillator’s developments, based on the use of the same type of high reliability resonators will be quickly describe. 2- FUNCTIONNAL REQUIREMENTS A large range of avionic or missile electronic systems, such as GPS receivers, radars, electronic war, missile guiding, requires the use of high stability oscillators. Their main electrical characteristics (frequency stability, warm-up, retrace, phase noise, spectral purity) must be obtained under severe environmental conditions (temperature, vibrations, shock), with a high reliability level. The last generation of airborne systems have been developed with new targets :

These objectives have direct consequences on the oscillator’s characteristics :

The main expected oscillator’s requirements can be summarize as follows : Electrical characteristics :

Environmental characteristics :

Reliability :

3- OSCILLATOR’S DESIGN - Crystal resonator In order to optimize the main requirements in tactical use, such as g sensitivity, retrace, aging, static and dynamic thermal behavior, SC cut crystals have been obviously chosen. 20 MHz and 10 MHz, 3rd overtone resonators have been tested. They are mounted in a low profile, 4 points T08 enclosure. The mounting structure is optimized for mechanical behavior under vibration and g sensitivity. The first internal mechanical resonances are above 5 KHz (3 axes), far away from the maximal environmental vibration frequencies. Fig [1] shows the experimental results of g sensitivity measurements. The average values are typically 2 / 3.10-10 / g, relatively independent form the excitation axis, as well as from the nominal frequency (10 / 20 MHz)

- Electronic functions A.R.Electronique has designed a specific, high reliability ASIC circuit, which includes the oscillator, the amplifier, as well as the voltage regulator and the oven control (LCC16 enclosure). The external adjustment components are SMD devices (see fig [2]).

- Mechanical and thermal design Classical OCXO’s disadvantages consist of long warm-up time and power consumption. In order to improve these parameters, only the crystal resonator is warmed. The heating temperature is set to the second turn-over point of the temperature curve (3 to 5°C upper than the maximum temperature limit) (). : SC cut crystal ovenized on 2nd T.O.P.

The crystal enclosure fixation on the PC board is designed in order to optimize at the same time the mechanical fastening and the thermal insulation : this aspect is critical for fast warm-up because of the extended temperature range (typical [–40, + 115]°C). The temperature sensitivity of the oscillator can not be consider as negligible : an electronic compensation is used in order to minimize it. The PC board is finally enclosed inside an hermetic metal package (economic standard size with specific mounting pins) (see fig [4]).

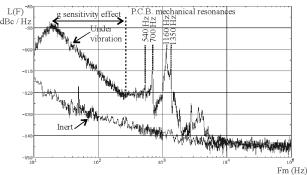

The different mounting and assembly techniques have been tested for reliability. 4-EXPERIMENTAL RESULTS 4-1 Phase noise under vibration As explained above, the environmental vibration on the oscillator is often degraded by the use of standard, non optimized mechanical structure. Fig [5] shows a practical example.

P.C.B. mechanical spurious frequencies : 540 Hz / 700 Hz / 1 160 Hz / 1 350 Hz A random vibration spectrum of 10g rms (10 to 2000 Hz) is applied on the device under test (one axis). On the base of the oscillator’s support, this level is multiplied with a factor of 2 to 5 in the same axis. In addition, transverse excitations appear in the perpendicular directions. These phenomenas are directly due to the mechanical resonances of the PCB support (between 500 to 1500 Hz). Fig [6] give the phase noise behavior of the oscillator mounted as described. Under 500 Hz, the phase noise value is directly connected with the modulation due to the resonator’s g sensitivity (about 2.10-10/g) :

Above 500 Hz, the support mechanical resonances (3 axes) induce large bandwidth spurious. Some characterizations have been done on the oscillator only : for frequencies lower than 2 KHz, the internal structure does not show any significative mechanical resonances. 4-2 Frequency stability versus temperature range The quality factor of the crystal’s thermal regulation is about 150 : for an external temperature range of –40 to +115°C, the regulated temperature on the crystal varies of about +/- 0,5°C. This induces a relatively low frequency drift about some 10-9. The major effect concerns the oscillator’s temperature sensitivity, which is highly connected to the crystal motional parameters, depending on the frequency. By using an adapted electronic compensation, it is possible to guarantee frequency stabilities as below : 10 MHz (SC cut, 3rd O.T. crystal) : +/-2.10-8 20 MHz (SC cut, 3rd O.T. crystal) : +/-1.10-7 Fig [7] shows an example of frequency vs temperature curve (-40, +115)°C.

The thermal behavior is characterized in the full temperature range, by applying a slope of 0,5 to +1,5°C / min (positive and negative senses). If better stability is required, it is no more possible to use the same thermal structure : the sensitive electronic circuitry must be ovenized. In this case, power consumption, warm-up time, will be degraded. Another interesting characterization tool is called I.T.G.E. (Internal Thermal Gradient Effect) : this parameter evaluates the frequency variation versus the oscillator’s orientation, at a stabilized temperature : this is a functional requirement for an airborne application. The g sensitivity effect (a few 10-10/g) can be consider as negligible for this type of OCXO. The I.T.G.E. order of value must be lower than the direct temperature effect : 10 MHz (SC, 3rd O.T.) : I.T.G.E. < +/-5.10-9 20 MHz (SC, 3rd O.T.) : I.T.G.E. < +/-2.10-8 (see Fig [8])

4-3 Warm-up As the oscillator is used on the same system for different applications, the warm-up requirements take two levels :

Because of the use of SC cut resonators, the start-up frequency offset can reach –150 to –200 ppm at lower temperature. The warm-up speed (point [2]) can be reduced by increasing the power consumption during start-up. However, this parameter must be optimized by considering the thermal structure of the oscillator.

Warm-up at –40°C

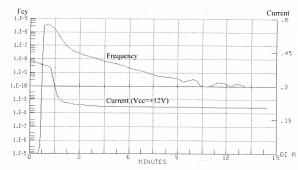

The lower temperature range is of course the most critical case. Fig [9] shows a typical warm-up characteristic (frequency, power consumption) of a 10 MHz miniaturized OCXO, at –40°C (power limit=5W) :

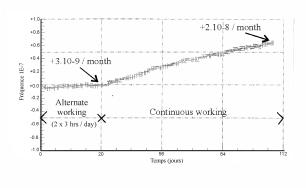

4-4 Aging – Retrace The characterization of these operational parameters must take into account the specificities of airborne working profile : alternate working on short periods (3- 6 hours), with long storage periods (1 day to 1 week). A.R.Electronique has launched a large measurement campaign on 18 months in order to characterize the behavior of these families of high stability miniature OCXO (10 and 20 MHz crystals). The increased oven temperature as well as the working storage profile effects were analysed on significative periods, as shown below :

Measurement results : - Aging : the oscillators are measured two times per day at ambient temperature. The aging slope per month is computed on the last 10 days of each phase.

As an example, Fig [10] shows the aging behavior of a 10 MHz OCXO, ovenized at +115°C. On this curve, the continuous / alternate working effect appears clearly.

10 MHz OCXO ovenized at 115°C

- Retrace : 14 retrace measurements have been done during 3 months (phase 5). Each cycle consists of one week inert storage (alternatively at temperatures –10°C, +115°C). The OCXOs are powered during 3 hours (frequency measurements 3 hours after turn-on). The relative value gives the frequency offset between two successive start-up. The cumulated value gives the absolute frequency offset after the whole retrace measurements period (3 months).

Results analysis As expected, the high temperature oven control effect is clearly identified : after increasing the oven temperature (phases 1, 2), the aging is immediately degraded with a factor of 5 to 10. However, this factor decreases significatively with the time : after about 1 year, the monthly aging at 115°C oven temperature reaches the same order of value than the initial aging at 85°C. The alternate working test (phases 2, 3, 4) shows that, as a first approximation, for high temperature oven control OCXOs, the aging is quite proportional to the effective working time. The retrace measurements must be analysed regarding the test profile (hard temperature cycling between measurements). The level of results are compatible with the expected values. All these tests have also confirmed the significative superiority of 10 MHz crystals compared with 20 MHz crystals. 5- CONCLUSION More than 18 months of experimental measurements under severe environmental conditions have confirmed the high level of performance and reliability of these new miniature high stability oscillators. Primarly designed for avionic, military requirements, the same families of crystal resonators have been introduced for other application fields. As preliminary approach, they have been tested also under specific space requirements (vacuum). For example : - high stability 10 MHz sources for avionic application : the PULSAR-EM family offers temperature stability range of 1.10-9 (electronic + crystal ovenized), in a aluminium airborne case. - compact OCXO type MICROSTAR for geophysical application (mud logging) : the specificities concern the very high working temperature and shock conditions. REFERENCES Valdois M., Besson J., and Gagnepain J.J. Influence of environment conditions on a quartz resonator : proc. 28th F.C.S. (1974) Filler R.L. and Vig J.R. The acceleration sensitivity of quartz crystal oscillators : a review. proc. 41st F.C.S. (1987)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||